Calling All CONTRACTORS

with Growing Teams...

You're the bottleneck because

everything lives in your head.

Are you looking to add more team members

and you know you'll get asked these questions?

What do you want me to do next?

When is the city inspection happening?

What do you want me to do after I finish demo?

How do you want me to paint the house?

What's the answer?

Keep reading...

For our promotion this month,

"Halloween Havoc,"

we are offering a

FREE

process documentation project.

Only 3 (of 5) are now available!!!

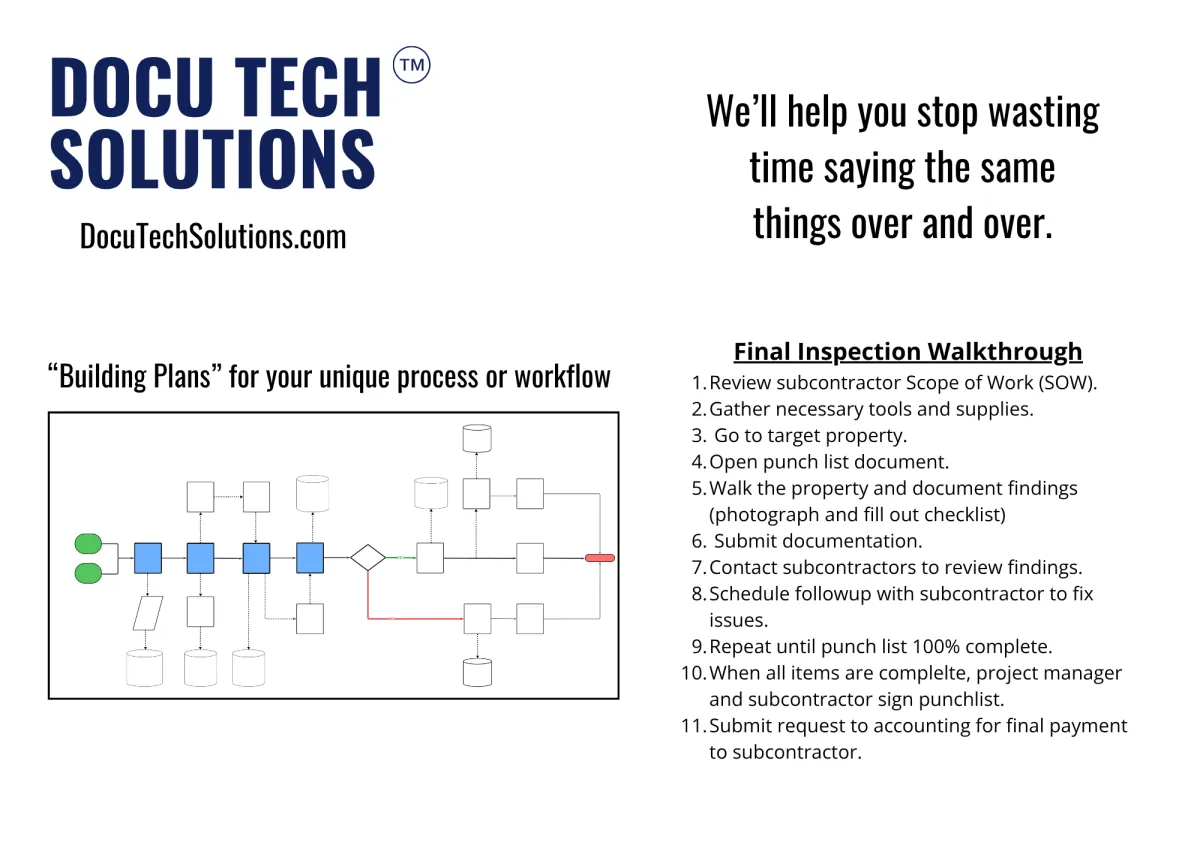

What the Docu Tech Solutions team will do is help you create a

"blueprint" for your construction process.

It may include a process diagram,

written work instructions instructions, or checklists.

It just depends on what you may need.

We treat these FREE projects like real client work.

All VALUE - no fluff.

After your project is done, if we feel you're a good fit to partner with us, we can discuss possible next steps, and you may be able to continue working with us.

We'll start with your

MOST URGENT PROBLEM

in your company.

In other words...

WHAT DO YOU NEED NOW?

Book on the calendar below to prevent:

Repeating yourself

Confusion

Bad instructions

Costly reworks

Missed steps

Constant questions

So that you can:

Spend more time with your family

Use your time to work ON the business

Grow your team and your business

Get to that next level

Book on the calendar below

ONLY if this is you...

Gross yearly revenue of > $1,000,000 / year

You are committed to getting better

You SHOW UP to the appointment

Willing to put in the work

The Simple 3-Step Solution

to Manufacturing Mastery

DOCUMENTATION: Create 100% accurate, clear, and visually appealing process documentation.

TRAINING: Train your engineers and technicians using these documents, tailored to their individual roles and learning styles.

FEEDBACK: Implement a "Kaizen" (continuous improvement) system to refine your processes based on real-world feedback.